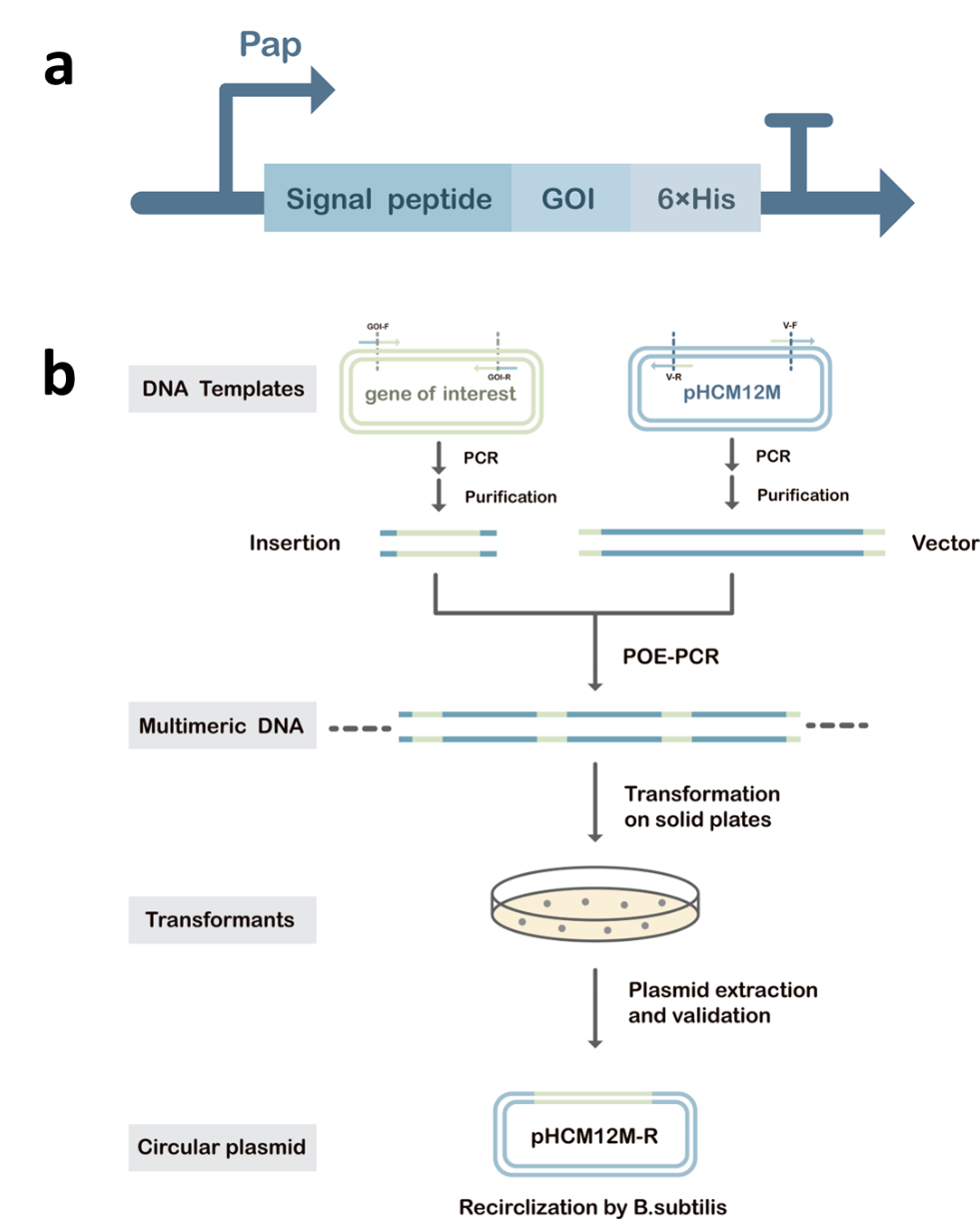

We first established an efficient secretion system within Bacillus subtilis. The signal peptide AprE was

fused to the

N-terminus of the enzymes to enable them to be effectively secreted out of the cells via the Sec pathway

(Figure 1a). In

B. subtilis, chaperones help the signal peptide to fold initially, and then SRP (signal recognition

particle) combines

with the signal peptide to form a complex. Chaperones, FtsY, and SecA together lead the enzyme to the Sec

transport

proteins. After the precursor protein traversing the membrane, the signal peptide is cleaved and degraded,

and the

extracellular chaperones assist the protein to form a stable conformation[1,

2]. Then we performed Prolonged Overlap

Extension PCR (POE-PCR) to separately polymerize the sequences of the three enzymes and the linearized

pHCM12M vector

into polymers (Figure 1b)[3], which were then transformed into Bacillus subtilis. To verify whether the

enzymes were

secreted out of the cells, we cultivated the bacterium on the plates with polycaprolactone (PCL), which can

be

hydrolyzed by lipases, esterases, keratinases and so on, commonly serving as a model substrate for assessing

the

extracellular secretion of hydrolases[4]. The observation of hydrolysis zones on the plates indicated

successful

expression and secretion of the enzymes.

Figure 1. (a) An efficient secretion pathway in Bacillus

subtilis. In the pathway there

is the Sec signal peptide AprE separately with the genes of interest (GOI) requiring secretion downstream of

it.

GOI include

IsPETase,

BsLipA, and Lipase1028. Downstream of the GOI is the 6×His tag for

the

purification of the protein;

(b) Flowchart of the prolonged overlap extension PCR (POE-PCR) process

for

the transformation of GOI into Bacillus subtilis SCK6. We obtain the linearized vector

and

DNA fragment with homologous arms by PCR reaction. During POE-PCR, GOI and the vector fragments are used

simultaneously as primers and templates to obtain linear multimeric DNA, which is transformed into the super

competent

Bacillus subtilis SCK6 and circularized later to form recombinant plasmids. Compared to

plasmid, multimeric DNA exhibits higher transformation efficiency when transformed into

Bacillus

subtilis[3].

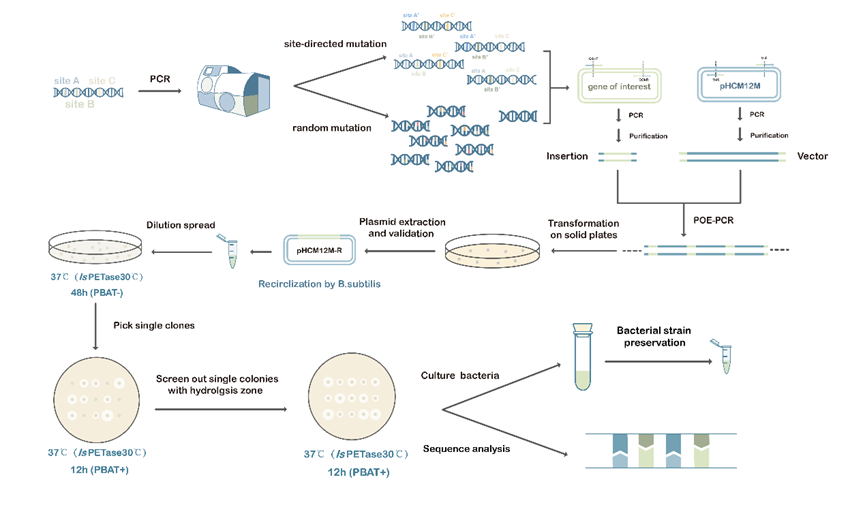

Figure 2. Construction and screening strategies for mutation libraries.

Pathway design of a FADS-based ultra-high-throughput evolution of PBAT-degrading enzyme

The method of screening by observing hydrolysis zones is common, straightforward, cost-effective, and simple

to

implement. However, its efficiency is limited a lot because of following drawbacks: (1) its throughput is

low (~104)[5]

; (2) human bias when selecting colonies may happen; (3) the measurement of hydrolysis zone size may lead

to errors

that affect the accuracy of the screening process; (4) the hydrolysis zones may overlap, making it

challenging to

accurately measure the size of each colony. Therefore, a high-throughput and precise screening method for

PBAT-degrading

enzymes in B.subtilis is needed.

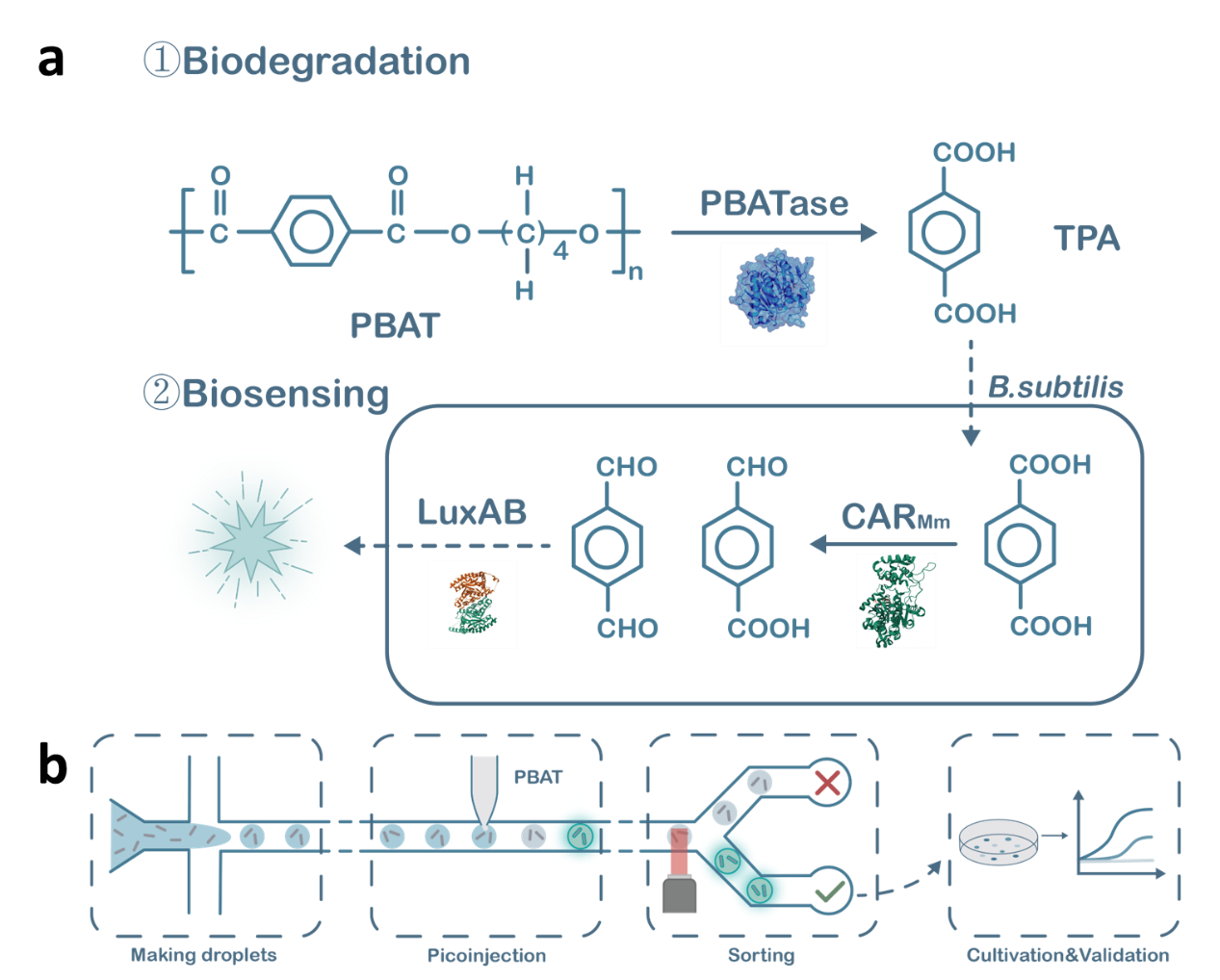

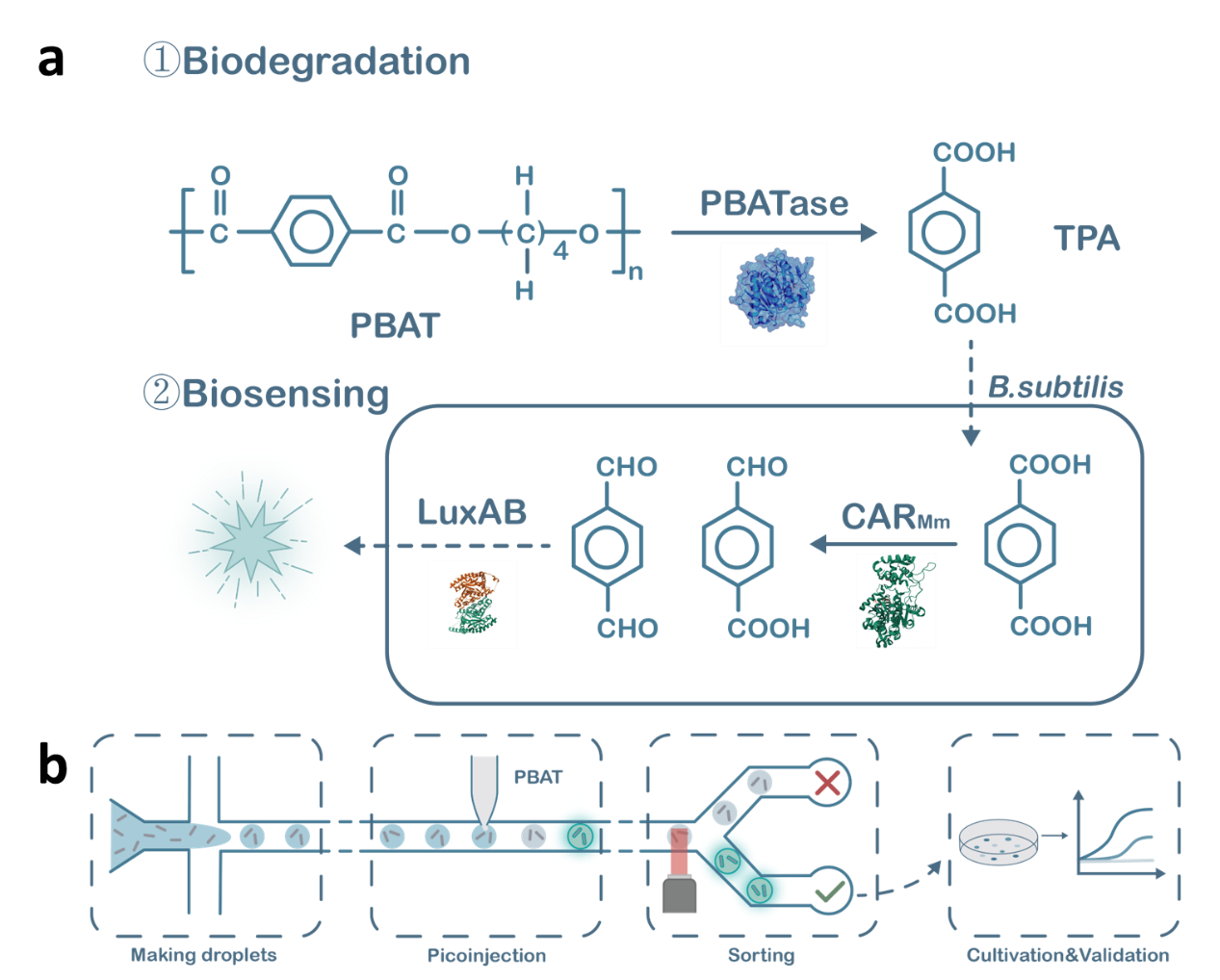

A biosensor system for sensing TPA has been developed (Figure 3a)[6]. In this system, carboxylic acid

reductase (CARMm)

from Mycobacterium marinum and the luciferase LuxAB from Photorhabdus luminescense have been transformed

into Bacillus

subtilis. TPA can enter the cells and be reduced to aldehyde by CARMm. Then, LuxAB utilizes the aldehyde as

a substrate

to produce the corresponding acid, generating bioluminescence. By measuring the bioluminescence intensity at

482 nm,

semi-quantitative detection of TPA can be achieved[6]. Our goal is to combine this system with FADS, which

couples the

activity of each variants with the fluorescence intensity, and finally facilitates high-throughput screening

(~107)

(Figure 3b) [5, 7].

Figure 3. Biosensor-based TPA detection coupled with bioluminescent FADS

screening.(a) An enzyme-coupled biosensor for detecting TPA produced by PBAT degradation. (1)

PBAT

enzymes degrade

PBAT, releasing

monomer molecules including TPA, BDO, and AA. The structure of the PBAT hydrolase is derived from our

evolutionarily

screened ND. (BDO and AA are not shown). (2) TPA can be reduced by CARMm to the corresponding dialdehyde

and

monoaldehyde (ligand molecule PPTNi not shown). These aldehydes serve as substrates for LuxAB to

generate

corresponding

acids and emit fluorescence, achieving bioluminescence. The excitation wavelength of the LuxAB reaction

is

482 nm, which

belongs to the visible cyan light spectrum. (b) Schematic diagram of FADS screening process. Bacillus

subtilis is

encapsulated in microfluidic droplets and incubated to allow cells to fully express PBAT hydrolase,

CARMm,

and LuxAB.

After a period of incubation, PBAT is injected into the microfluidic droplets to generate a fluorescent

signal.

Fluorescence signal detection and sorting are then performed to separate target droplets from non-target

droplets.

Droplets with strong fluorescence signals typically contain the target enzymes or cells with specific

biochemical

reaction products, while droplets with weaker fluorescence signals are considered non-target droplets. A

highly active

PBAT enzyme can degrade more TPA and achieve a higher level of luminescence.

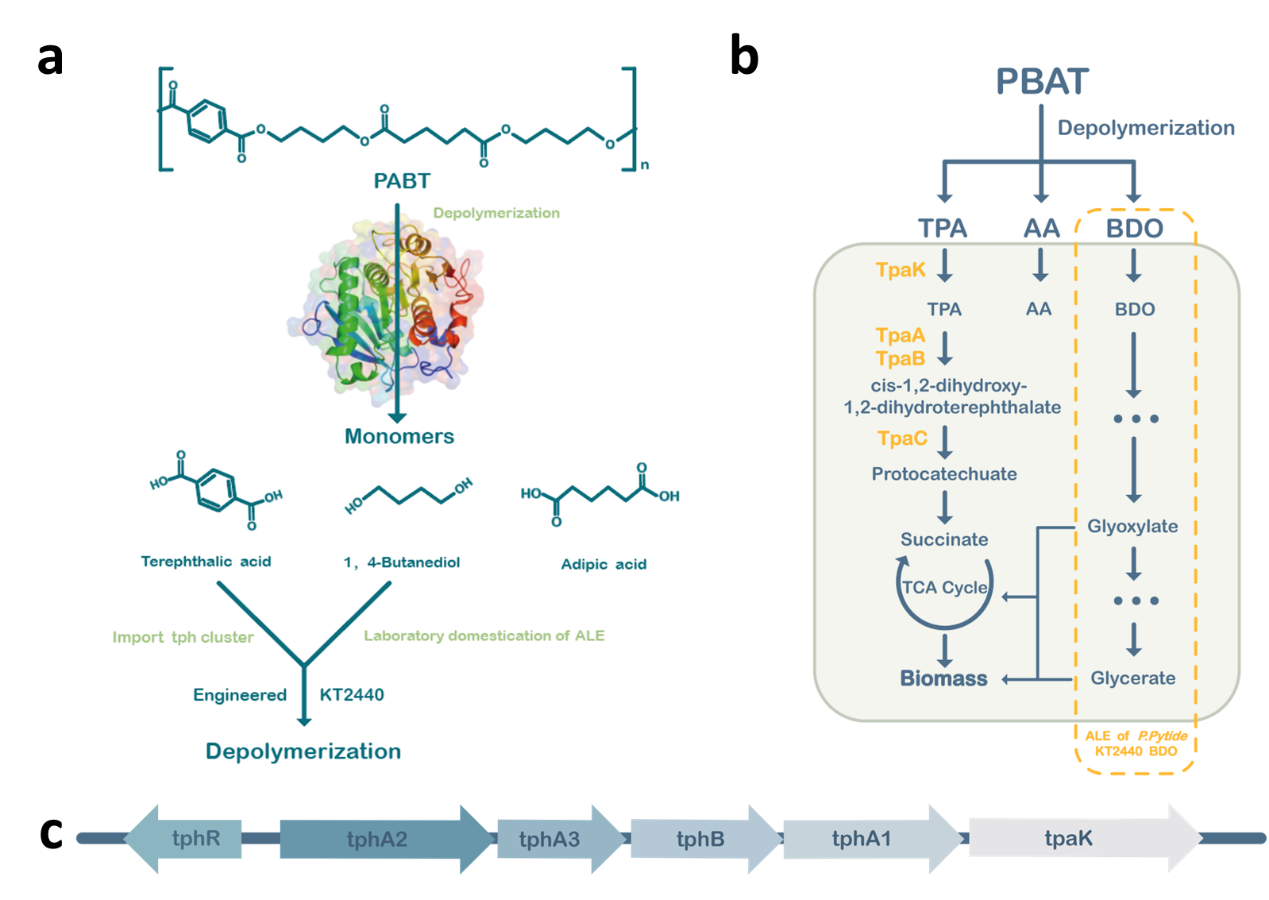

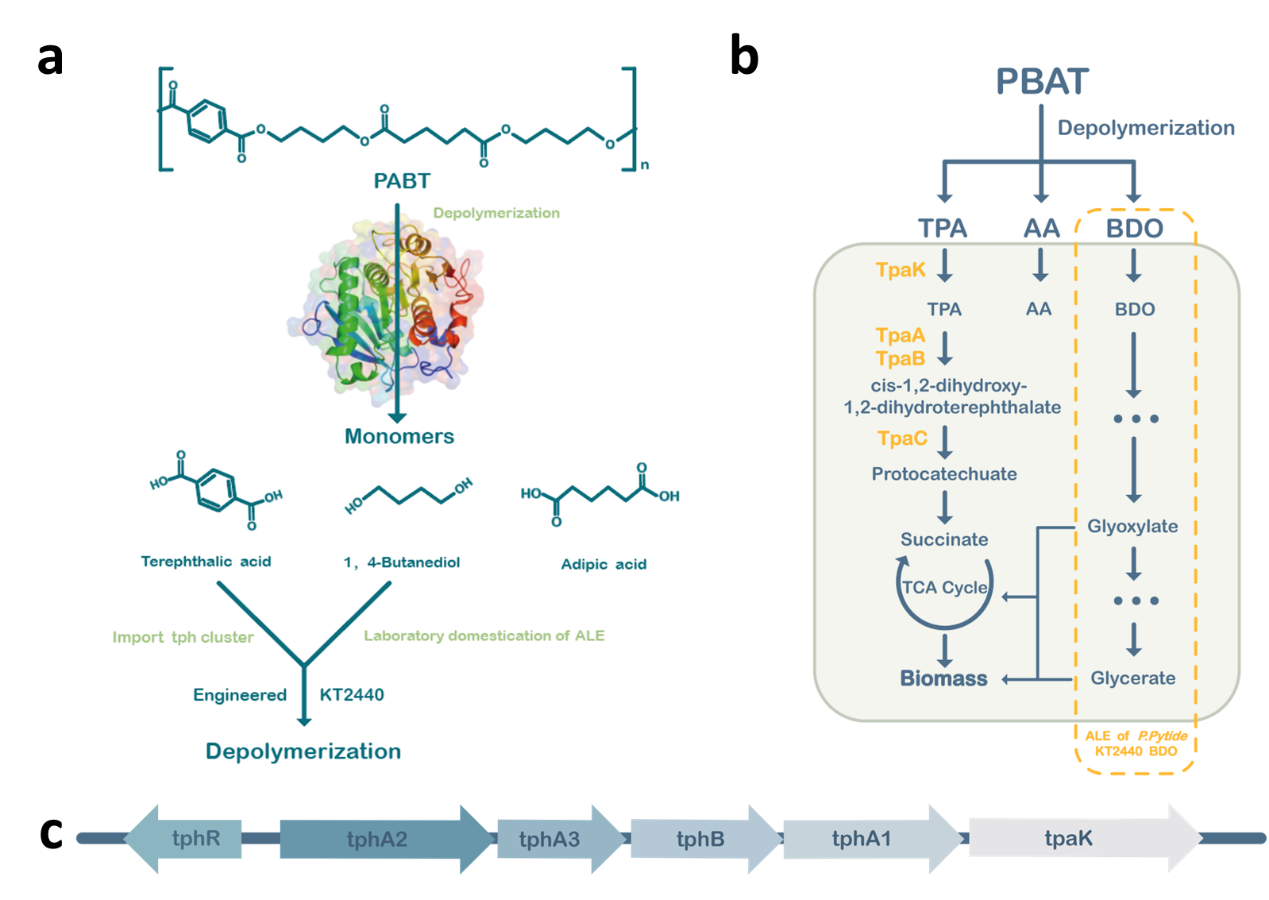

Engineered KT2440 Strain Construction and ALE-Derived Mutant Isolation for TPA and BDO

Utilization

To upcycle PBAT, a multifunctional P. putida KT2440 strain was engineered to secrete PET hydrolase and

degrade PBAT

hydrolysates TPA and BDO (Figure 4a). The engineering involved: (1) transforming the tph gene cluster into

KT2440 for

constitutive expression; (2) adaptive laboratory evolution (ALE) of KT2440-tph to utilize TPA and

1,4-butanediol; (3)

transforming evolved mutants into KT2440-tph. The tph gene cluster from Pseudomonas stutzeri TPA3 was

electroporated

into KT2440, enabling TPA degradation (Figure 3b and 3c). ALE experiments with wild-type and engineered

strains in

mineral salt medium supplemented with 1,4-butanediol and TPA showed increased growth rates, indicating

enhanced

utilization of BDO and TPA. Further ALE is planned to improve degradation efficiency.

Figure 4. (a) The construction process for engineered KT2440.The

engineering modification of Pseudomonas putida KT2440 mainly consists of three parts: (1) transforming

the tph gene

cluster into KT2440 to obtain KT2440-tph and expressing the gene cluster constitutively; (2) adaptive

laboratory

evolution (ALE) of KT2440-tph to enable the utilization of TPA as carbon sources and a certain concentration

of

1,4-butanediol; (3) transforming the mutants into the evolved KT2440-tph. (b) An engineered P. putida strain

with

abilities of PBAT depolymerization and co-degradation of TPA and BDO. Schematic of a single engineered

strain

Pseudomonas putida KT2440 capable of degrading PBAT and co-degrading its degradation products TPA and BDO.

The entire

tph gene cluster was transformed into KT2440 and constitutively expressed to achieve co-degradation of TPA

and BDO. (c)

The feature of tph cluster. A tph cluster containing genes encoding the transcriptional regulator (tphR),

tpa

transporter (tpaK), tpa 1, 2-dioxygenase (tphA), and 1, 2-dihydroxy-3, 5-cyclohexadiene-1, 4-dicarboxylate

dehydrogenase

(tphB).

Reference

-

[1] M. Hao, W. Hui, L. Shao, C. Shi, F. Lu and H. Zhang, Improving the Ability of

Bacilluslicheniformisto Produce

Alkaline Protease by Inactivating Sec Pathway Repressor Protein and Extracellular Proteases, China

Biotechnology, 44, 39-47, (2024).

DOI: https://doi.org/10.13523/j.cb.2307018

-

[2] J. de Keyzer, C. van der Does and A. J. M. Driessen, The bacterial translocase: a dynamic protein

channel

complex, Cellular and Molecular Life Sciences, 60, 2034-2052, (2003).

DOI: https://doi.org/10.1007/s00018-003-3006-y

-

[3] U. Canosi, G. Morelli and T. A. Trautner, The relationship between molecular structure and

transformation

efficiency of some S. aureus plasmids isolated from B. subtilis, Molecular & general genetics :

MGG,

166, 259-67, (1978).

DOI: https://doi.org/10.1007/bf00267617

-

[4] S. M. Satti and A. A. Shah, Polyester-based biodegradable plastics: an approach towards sustainable

development,

Letters in Applied Microbiology, 70, 413-430, (2020).

DOI: https://doi.org/10.1111/lam.13287

-

[5] Y. Joho, V. Vongsouthi, C. Gomez, J. S. Larsen, A. Ardevol and C. J. Jackson, Improving plastic

degrading

enzymes via directed evolution, Protein Eng Des Sel, 37, (2024).

DOI: https://doi.org/10.1093/protein/gzae009

-

[6] T. Bayer, L. Pfaff, Y. Branson, A. Becker, S. Wu, U. T. Bornscheuer, et al., Biosensor and

chemo-enzymatic

one-pot cascade applications to detect and transform PET-derived terephthalic acid in living cells,

iScience, 25, 104326, (2022).

DOI: https://doi.org/10.1016/j.isci.2022.104326

-

[7] Y. Qiao, R. Hu, D. Chen, L. Wang, Z. Wang, H. Yu, et al., Fluorescence-activated droplet sorting of

PET

degrading microorganisms, J Hazard Mater, 424, 127417, (2022).

DOI: https://doi.org/10.1016/j.jhazmat.2021.127417