Background

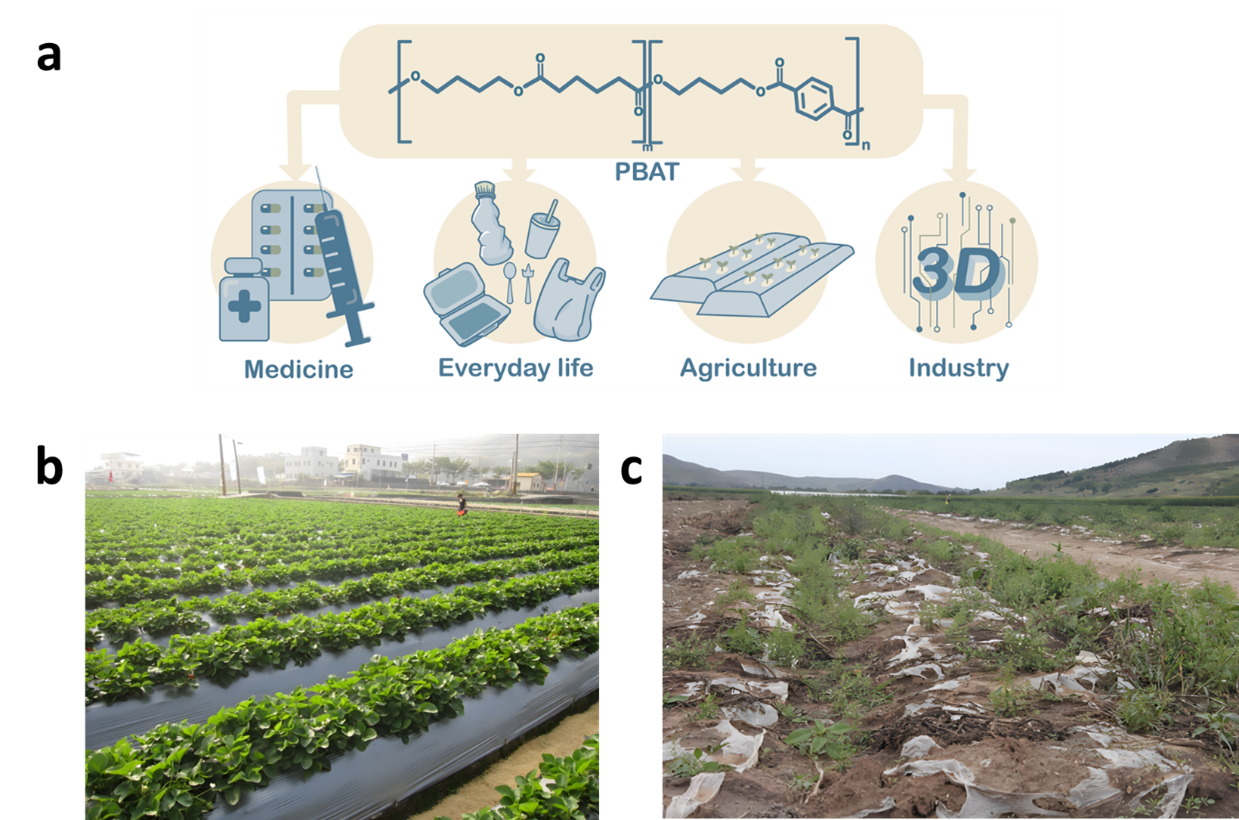

Poly (butylene adipate-co-terephthalate) (PBAT), a polymer synthesized from the monomers terephthalic acid

(TPA),

adipic

acid (AA), and 1,4-butanediol (BDO), has garnered significant attention as a biocompatible and degradable

polymeric

material, exhibiting considerable potential for widespread application in the realm of agricultural film

technology

(Figure 1a)[1-3]. However, owever, the consequences of the growing and hard-to-reverse issue of polyethylene films on our planet are challenging, affecting both the physical environment and living organisms (Figure 1b and c)[4-8].

Figure 1. (a) PBAT has a wide range of applications in various fields. (b) The use of PBAT agricultural film in agriculture. PBAT agricultural film can effectively reduce weeds and pests, regulate soil temperature, improve water retention capacity, reduce soil erosion, and increase crop yields by 20% to 60%.

(c) Abandoned PBAT agricultural film causes large-scale plastic pollution.

Biodegradation of PBAT meets challenges

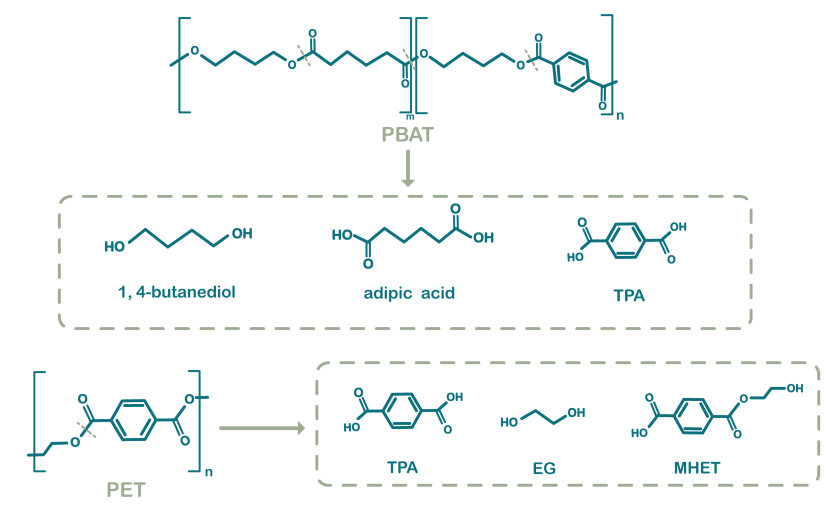

As an eco-friendly and sustainable strategy to reduce and recycle plastic waste, biodegradable catalysts

using enzymes

or microorganisms meet some challenges. Firstly, the degradation of PBAT yields a mixture of TPA and AA with

distinct

physical and chemical properties (Figure 2). Microorganisms typically encounter carbon catabolite repression

when

confronted with this varied substrate mix, impeding their ability to utilize multiple substrates

simultaneously.

Additionally, PBAT hydrolysis products can be toxic, adversely affecting microbial metabolism and efficient

substrate

assimilation, particularly at high concentrations or with crude hydrolysates[9-11].

Figure 2. Chemical structures of PBAT and PET and respective ester hydrolysis products.

The hydrolysis products of PBAT contain terephthalic acid (TPA), adipic acid (AA) and 1,4-butanediol

(BDO)[3]

.

Biodegradation of PET also produces TPA, suggesting that certain enzymes that degrade PET have the potential

to degrade

PBAT.

Existing PBAT-degrading enzymes and microorganisms typically require high temperatures (50-65℃) for effective

composting

(Table 1) [12]. Jia et al. identified a serine hydrolase enzyme from

Thermobifida fusca FXJ-1 capable of

degrading PBAT

at 55℃, while Wallace et al. utilized proteomics to isolate an esterase from Pseudomonas pseudoalcaligenes

effective at

65℃[13]. Nevertheless, the PBAT decomposition rates of existing

PBAT-degrading enzymes in room temperature

are generally

low, restricting its utilization in the context of agricultural practices[14]. Moreover, Wang et al.

reported that the

degradation rate of PBAT films in conventional agricultural soil was only 2.3% over a three-month

period[15].

Table 1. Enzymes with PBAT degradation developed in recent years

| Enzyme |

Classification |

Source |

Activity (mol/mol)* |

PBAT |

Condition |

Ref. |

Genbank |

| PfL1 |

Lipase |

Pelosinus Fermentans |

~130 |

Film

Milled |

50°C 72h |

[16] |

EIW29778.1 |

| PpEst |

Esterase |

Pseudomonas pseudoalcaligenes |

~8~70 |

Film

Milled |

65°C 72h |

[17] |

W6R2Y2 |

| Cbotu_EstA |

Esterase |

Clostridium Botulinum |

<30 |

Not specified |

50°C 72h |

[17] |

CAL82416.1 |

| Cbotu_EstB |

Esterase |

Clostridium botulinum |

~12 |

Not specified |

37°C 72h |

[17] |

CAL83600.1 |

| TfCut |

Cutinase |

Thermobifida fusca |

5198 |

Film |

70°C 48h |

[3] |

CBY05530 |

| IsPETase |

Cutinase |

Ideonella sakaiensis |

4868 |

Film |

30°C 48h |

[3] |

A0A0K8P6T7 |

| PbPL |

Cutinase |

Polyangium brachysporum |

- |

Film |

30°C 48h |

- |

- |

| BurPL |

Cutinase |

Burkholderiales bacterium |

3208 |

Film |

35°C 48h |

[3] |

- |

| Ple628 |

Hydrolases |

Marine microbial consortium |

121 |

Film |

30°C 144h |

[18] |

OK558824 |

| Ple629 |

Hydrolases |

Marine microbial consortium |

1704 |

Film |

30°C 72h |

[18] |

OK558825 |

| HiC |

Cutinase |

Humicola insolens |

~10,000 |

Film |

50°C 72h |

[17] |

A0A075B5G4 |

| LCC |

Cutinase |

Leaf-branch compost |

4636 |

Film |

70°C 24h |

[3] |

G9BY57.1 |

| ICCG |

Cutinase |

Leaf-branch compost |

5275 |

Film |

75°C 24h |

[3] |

USU85609.1 |

| TcCut |

Cutinase |

Thermobifida cellulolysitica |

5361 |

Film |

65°C 48h |

[3] |

ADV92526.1 |

*The activity is the quantitation of products containing TPA and BTa (mol) per mol enzymes. -

refers

to not find.

Our goal

In this work, we identified three distinct enzyme candidates for targeted evolutionary engineering, with the

objective of developing highly efficient PBAT-degrading enzymes that exhibit optimal catalytic activity

under room temperature conditions. These enzyme candidates include IsPETase, a cutinase derived from

the PET-degrading bacterium Ideonella sakaiensis; BsLipA, a lipase from Bacillus subtilis; and

Lipase1028, which has been newly isolated in our laboratory. IsPETase is capable of degrading PET in

the glassy state at moderate temperatures (30-37°C)[19-22]. BsLipA exhibits

good hydrolytic activity on ester bonds formed by medium-chain fatty acids[23,

24]. Lipase1028 demonstrates significant degradation capabilities for polyurethanes (PU). Based

on the structural similarities between the substrates of these three enzymes and PBAT, we propose that all

three possess considerable evolutionary potential[3, 25].

Furthermore, we also aim to obtain an engineering single strain capable of catabolizing of PBAT-derived

degradation products. Pseudomonas putida has been recognized as a potential host organism for a

diverse range of biotechnological applications, including the metabolic processing of plastics [26, 27]. Wing-Jin Li et al. reported that the wild-type Pseudomonas

putida KT2440 could degrade TPA but at a very slow rate, requiring over 50 hours to degrade 20 mM

substrate[28]. In this study, we transformed the gene cluster tph

derived from Pseudomonas stutzeri TPA3 into KT2440 to enable its degradation of TPA[29, 30]. Then, we performed adaptive laboratory evolution and metabolic

engineering to isolate KT2440 variants capable of utilizing 1,4-butanediol as the sole carbon source.

Ultimately, we will transform the evolved PBAT degradation enzyme genes which are obtained from directed

evolution, into the engineered KT2440 strain, aiming to create a single strain capable of efficiently

degrading PBAT and utilizing its degradation products, thus facilitating sustainable degradation processes

eventually.

Reference

-

[1] A. Kanwal, M. Zhang, F. Sharaf and C. Li, Polymer pollution and its solutions with special emphasis

on

Poly (butylene adipate terephthalate (PBAT)), Polymer Bulletin, 79, 9303-9330, (2022).

DOI: https://doi.org/10.1007/s00289-021-04065-2

-

[2] S. Roy and J.-W. Rhim, Curcumin Incorporated Poly(Butylene Adipate-co-Terephthalate) Film with

Improved

Water Vapor Barrier and Antioxidant Properties, Materials, 13, (2020).

DOI: https://doi.org/10.3390/ma13194369

-

[3] Y. Yang, J. Min, T. Xue, P. Jiang, X. Liu, R. Peng, et al., Complete bio-degradation of

poly(butylene

adipate-co-terephtalate) via engineered cutinases, Nature Communications, 14, (2023).

DOI: https://doi.org/10.1038/s41467-023-37374-3

-

[4] M. C. Rillig, Microplastic in Terrestrial Ecosystems and the Soil?, Environmental Science &

Technology, 46, 6453-6454, (2012).

DOI: https://doi.org/10.1021/es302011r

-

[5] Z. Liu, F. Huang, B. Wang, Z. Li, C. Zhao, R. Ding, et al., Soil respiration in response to biotic

and

abiotic factors under different mulching measures on rain-fed farmland, Soil & Tillage Research,

232, (2023).

DOI: https://doi.org/10.1016/j.still.2023.105749

-

[6] Z. Steinmetz, C. Wollmann, M. Schaefer, C. Buchmann, J. David, J. Troeger, et al., Plastic mulching

in

agriculture. Trading short-term agronomic benefits for long-term soil degradation?, Science of the

Total

Environment, 550, 690-705, (2016).

DOI: https://doi.org/10.1016/j.scitotenv.2016.01.153

-

[7] R. M. Qi, D. L. Jones, Z. Li, Q. Liu and C. R. Yan, Behavior of microplastics and plastic film

residues in

the soil environment: A critical review, Science of the Total Environment, 703,

(2020).

DOI: https://doi.org/10.1016/j.scitotenv.2019.134722

-

[8] D. Brennecke, B. Duarte, F. Paiva, I. Caçador and J. Canning-Clode, Microplastics as vector for

heavy metal

contamination from the marine environment, Estuarine Coastal and Shelf Science, 178,

189-195,

(2016).

DOI: https://doi.org/10.1016/j.ecss.2015.12.003

-

[9] M. N. Kim, B. Y. Lee, I. M. Lee, H. S. Lee and J. S. Yoon, Toxicity and biodegradation of products

from

polyester hydrolysis, Journal of Environmental Science and Health Part a-Toxic/Hazardous Substances &

Environmental Engineering, 36, 447-463, (2001).

DOI: https://doi.org/10.1081/ese-100103475

-

[10] J. F. Pang, M. Y. Zheng, R. Y. Sun, A. Q. Wang, X. D. Wang and T. Zhang, Synthesis of ethylene

glycol and

terephthalic acid from biomass for producing PET, Green Chemistry, 18, 342-359,

(2016).

DOI: https://doi.org/10.1039/c5gc01771h

-

[11] K. Varaprasad, M. Pariguana, G. M. Raghavendra, T. Jayaramudu and E. R. Sadiku, Development of

biodegradable metaloxide/polymer nanocomposite films based on poly-e-caprolactone and terephthalic acid,

Materials Science and Engineering C-Materials for Biological Applications, 70, 85-93,

(2017).

DOI: https://doi.org/10.1016/j.msec.2016.08.053

-

[12] P. Svoboda, M. Dvorackova and D. Svobodova, Influence of biodegradation on crystallization of poly

(butylene

adipate-co-terephthalate), Polymers for Advanced Technologies, 30, 552-562, (2019).

DOI: https://doi.org/10.1002/pat.4491

-

[13] X. Jia, K. Zhao, J. Zhao, C. Lin, H. Zhang, L. Chen, et al., Degradation of poly(butylene

adipate-co-terephthalate) films by Thermobifida fusca FXJ-1 isolated from compost, Journal of

Hazardous

Materials, 441, (2023).

DOI: https://doi.org/10.1016/j.jhazmat.2022.129958

-

[14] A. Chorolque, C. Pozzo Ardizzi, G. Pellejero, G. Aschkar, F. J. García Navarro and R. Jiménez

Ballesta,

Incidence of bacterial diseases associated with irrigation methods on onions (Allium cepa), J

Sci Food

Agric, 98, 5534-5540, (2018).

DOI: https://doi.org/10.1002/jsfa.9101

-

[15] H. Wang, D. F. Wei, A. N. Zheng and H. N. Xiao, Soil burial biodegradation of antimicrobial

biodegradable PBAT

films, Polymer Degradation and Stability, 116, 14-22, (2015).

DOI: https://doi.org/10.1016/j.polymdegradstab.2015.03.007

-

[16] A. Biundo, A. Hromic, T. Pavkov-Keller, K. Gruber, F. Quartinello, K. Haernvall, et al.,

Characterization of a

poly(butylene adipate-co-terephthalate)- hydrolyzing lipase from Pelosinus fermentans, Appl

Microbiol

Biotechnol, 100, 1753-1764, (2016).

DOI: https://doi.org/10.1007/s00253-015-7246-4

-

[17] V. Perz, A. Baumschlager, K. Bleymaier, S. Zitzenbacher, A. Hromic, G. Steinkellner, et al.,

Hydrolysis of

synthetic polyesters by Clostridium botulinum esterases, Biotechnol Bioeng, 113,

1024-34,

(2016).

DOI: https://doi.org/10.1002/bit.25874

-

[18] I. E. Meyer Cifuentes, P. Wu, Y. Zhao, W. Liu, M. Neumann-Schaal, L. Pfaff, et al., Molecular and

Biochemical

Differences of the Tandem and Cold-Adapted PET Hydrolases Ple628 and Ple629, Isolated From a Marine

Microbial

Consortium, Front Bioeng Biotechnol, 10, 930140, (2022).

DOI: https://doi.org/10.3389/fbioe.2022.930140

-

[19] S. Yoshida, K. Hiraga, T. Takehana, I. Taniguchi, H. Yamaji, Y. Maeda, et al., A bacterium that

degrades and

assimilates poly(ethylene terephthalate), Science, 351, 1196-1199, (2016).

DOI: https://doi.org/10.1126/science.aad6359

-

[20] X. Han, W. D. Liu, J. W. Huang, J. T. Ma, Y. Y. Zheng, T. P. Ko, et al., Structural insight into

catalytic

mechanism of PET hydrolase, Nature Communications, 8, (2017).

DOI: https://doi.org/10.1038/s41467-017-02255-z

-

[21] C. C. Chen, X. Han, X. Li, P. C. Jiang, D. Niu, L. X. Ma, et al., General features to enhance

enzymatic

activity of poly(ethylene terephthalate) hydrolysis, Nature Catalysis, 4, 425-430,

(2021).

DOI: https://doi.org/10.1038/s41929-021-00616-y

-

[22] T. Fecker, P. Galaz-Davison, F. Engelberger, Y. Narui, M. Sotomayor, L. P. Parra, et al., Active

Site

Flexibility as a Hallmark for Efficient PET Degradation by I-sakaiensis PETase, Biophysical

Journal,

114, 1302-1312, (2018).

DOI: https://doi.org/10.1016/j.bpj.2018.02.005

-

[23] K. E. Jaeger and T. Eggert, Lipases for biotechnology, Current Opinion in Biotechnology,

13,

390-397, (2002).

DOI: https://doi.org/10.1016/s0958-1669(02)00341-5

-

[24] P. Bracco, N. van Midden, E. Arango, G. Torrelo, V. Ferrario, L. Gardossi, et al., Bacillus

subtilis Lipase

A—Lipase or Esterase?, Catalysts, 10, (2020).

DOI: https://doi.org/10.3390/catal10030308

-

[25] F. Muroi, Y. Tachibana, P. Soulnetohne, K. Yamamoto, T. Mizuno, T. Sakurai, et al.,

Characterization of a

poly(butylene adipate-co-terephthalate) hydrolase from the aerobic mesophilic bacterium Bacillus

pumilus,

Polymer Degradation and Stability, 137, 11-22, (2017).

DOI: https://doi.org/10.1016/j.polymdegradstab.2016.08.053

-

[26] N. Wierckx, M. A. Prieto, P. Pomposiello, V. de Lorenzo, K. O'Connor and L. M. Blank, Plastic waste

as a novel

substrate for industrial biotechnology, Microbial Biotechnology, 8, 900-903, (2015).

DOI: https://doi.org/10.1111/1751-7915.12312

-

[27] R. A. Wilkes and L. Aristilde, Degradation and metabolism of synthetic plastics and associated

products by

Pseudomonas sp.: capabilities and challenges, Journal of Applied Microbiology, 123,

582-593,

(2017).

DOI: https://doi.org/10.1111/jam.13472

-

[28] W. J. Li, T. Narancic, S. T. Kenny, P. J. Niehoff, K. O'Connor, L. M. Blank, et al., Unraveling

1,4-Butanediol

Metabolism in Pseudomonas putida KT2440, Frontiers in Microbiology, 11, (2020).

DOI: https://doi.org/10.3389/fmicb.2020.00382

-

[29] P. Liu, T. Zhang, Y. Zheng, Q. Li, Q. Liang and Q. Qi, Screening and genome analysis of a

Pseudomonas

stutzeri that degrades PET monomer terephthalate, Acta Microbiologica Sinica, 62,

200-212,

(2022).

DOI: https://doi.org/10.13343/j.cnki.wsxb.20210178

-

[30] P. Liu, Y. Zheng, Y. B. Yuan, T. Zhang, Q. B. Li, Q. F. Liang, et al., Valorization of Polyethylene

Terephthalate to Muconic Acid by Engineering Pseudomonas Putida, International Journal of

Molecular

Sciences, 23, (2022).

DOI: https://doi.org/10.3390/ijms231910997