What is HMA?

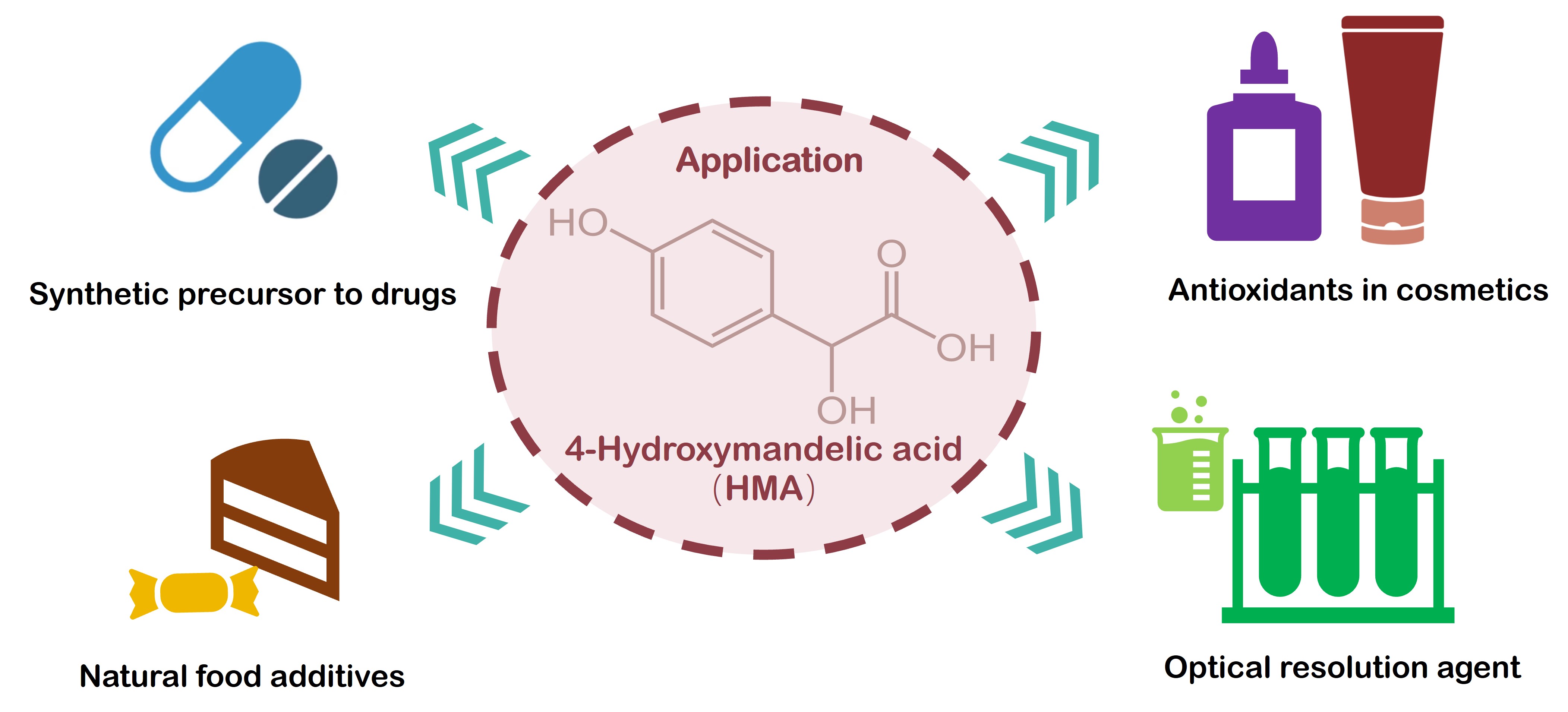

Four-hydroxymandelate (HMA) is an aromatic molecule that has a high application value in various fields, such as medicine, cosmetics, food and chemical industry[1]. In the pharmaceutical field, HMA serves as a precursor for the synthesis of various drugs and a variety of medications for cancers, allergies and diabetes. In the cosmetics industry, HMA is also frequently added to beauty products due to its relatively high antioxidant capacity compared to α-tocopherol. In the food and flavor synthesis field, ethyl vanillin, a derivative of HMA, has great prospects due to its sweet chocolate aroma[2]. HMA in a specific conformation can react with prochiral substrates to produce designated chiral products with high purity, which represents a highly popular biocatalytic method in the fine chemical industry.

Problems

The existing methods to obtain HMA include chemical synthesis and biological synthesis. Major chemical methods for extraction involve the condensation reaction of phenol and glyoxylic acid, as well as electrochemical reactions of phenol and trichloroacetaldehyde. Clearly, these methods give rise to serious environmental pollution and the discharged wastewater can corrode various equipment. In actual production, it is also necessary to consider the issues regarding high cost of raw materials and low purity of products.

In the biocatalytic synthesis of HMA, the key step is the conversion of 4-hydroxyphenylpyruvate (HPP) to 4-hydroxymandelate (HMA) catalyzed by hydroxymandelate synthase (HmaS). Noteworthily, the activity of HmaS is a limited factor exhibiting a conversion rate of only 19.4%. This bottleneck in the crucial conversion step limits the production of HMA and has become the focus of our research.

Strategy

In this study, we planned to increase HMA yield by two methods

Constructing an Upstream Chassis Strain with a High-yield Precursor

We considered that the substrate HPP in the 4-hydroxymandelate synthesis pathway is a high-value aromatic compound. We decided to engineer an Escherichia coli (E. coli) strain with high HPP production by metabolic engineering, such as gene overexpressing and gene interference.

Boosting the Key Enzyme Activity Downstream

We planned to use directed evolution to improve the activity of the key enzymes, HmaS. Using a Dual-Module Screening Platform based on high-throughput screening biosensor to rapidly screen dominant clones. For more information, please visit the Design.